From cocoa to chocolate: we guarantee the control of the entire production chain.

ICAM is one of the few chocolatier companies in the world to ensure the control of the entire production chain, a business choice that, starting from the selection of producers of absolute quality, ensures the maintenance of the highest standards of quality in every phase of production.

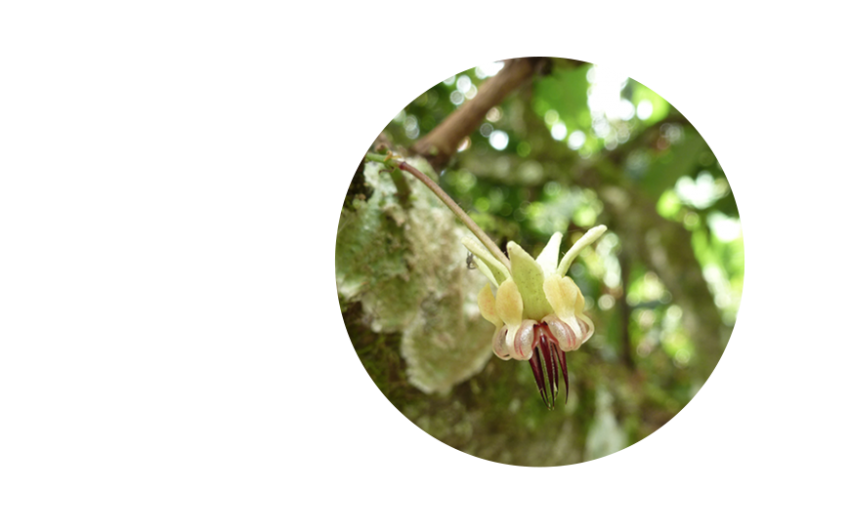

The plantation

control of the supply chain starts from the plantations, where the ideal conditions are reproduced, typical of the natural forest with high tree, to ensure the shade necessary for optimal growth of the cocoa trees, which do not tolerate direct light and temperature variations.

The cultivation

The commitment of ICAM in the plantations also extends to the study and realisation of projects that will improve productivity. To this end ICAM has been gradually introducing a revolutionary new concept: implementing the number of varieties of clones. Of the thousands of small white or yellow-pink flowers that every year grow on the cocoa tree, only 1% become fruit, the pods. That is why it is important, to increase productivity, to implement the number of varieties of cocoa, in addition to the three known so far, which are the Criollo; the Forastero and the Trinitario.

– Criollo Cocoa

Criollo accounts for about 2% of world cocoa production. It is a very fine cocoa, with a delicate and sensitive quality.

– Forastero Cocoa

Forastero instead accounts for the majority of world cocoa production, about 80%. It comes mainly from South America, in particular from the Amazon, and is characterised by the violet beans and green pods that, when mature, take on a yellow/red colouration.

– Trinitario Cocoa

Trinitario, a cocoa originating in Trinidad, is instead a hybrid of the previous two varieties of cocoa and accounts for approximately 18% of world production.

Harvesting and fermentation

The moment of harvesting and fermentation is a very delicate phase. It requires, in fact, the maximum experience and skill to be able to cut the pods without damaging the beans contained within. The entire operation must be done by hand with the utmost care. After harvesting, the beans and the pulp are extracted and stored in crates, left to rest for a few days (up to 5/6 days). This is the period in which all the phases of fermentation occur: yeast, lactic and then acetic.

Drying and quality control

The phase of drying is a particularly important moment to ensure the quality of the cocoa. Drying allows the cocoa bean to be conserved and it blocks the fermentation process. If it lasts too long, in fact, fermentation can cause excessive acidity. All beans are then subjected to thorough quality control and from here are collected in sacks and shipped to the factory.

The arrival in the production plant

Once they have reached the new production plant of ICAM in Orsenigo, the control of the supply chain continues in the decisive stages of transformation from cocoa chocolate:

Analysis

Preliminary tests and Cleaning

There is a check on the level of fermentation and for the absence of defects. The cocoa is cleaned of any foreign matter and is selected by dividing the broken beans from the whole ones, which will continue the process.

Pretoasting

The beans are subjected for about 100 seconds to strong infrared irradiation at about 400° which facilitates the separation of the skin from the bean.

Grain

Breaking

The beans are broken up into small pieces (grain)and at the same time, the skin that covers them is eliminated.

Alkalising

The grain undergoes a “bath” with water to which, for some productions, potassium carbonate can be added, which reduces the natural acidity of the cocoa.

Cocoa paste

Toasting

The grain is toasted with hot air from 100° to 120°. The process of toasting lasts approximately 30 minutes and should guarantee homogeneous toasting so that it can develop the noblest aromas of the cocoa.

Grinding

The grain is ground in a grinding mill and here it is transformed into cocoa liquor or cocoa paste.

Squeezing

The cocoa paste is squeezed in hydraulic presses, which extract the fatty part, the butter; the dry part remaining from the squeezing of the cocoa paste is the cake of cocoa, from which cocoa powder is obtained.

Cocoa butter

Filtration

The cocoa butter is filtered with paper sieves that are able to retain any impurities.

Deodorisation

The cocoa butter is subjected to a deodorisation process. By means of a high-pressure steam jet, part of the volatile acids is extracted to soften the taste of the butter.

Cocoa powder

Pulverisation

The cake is crushed and then chopped until finely pulverising it, obtaining the cocoa powder. At this point the cocoa is ready to be packaged for sale.

Mixing

The ingredients (cocoa paste and cocoa butter, sugar, powdered milk and – for gianduia- hazelnut paste) are selected and mixed in varying proportions, depending on the recipe and the type of chocolate that one wants to obtain: milk, white, dark chocolate, gianduia.

Refining

Large cylindrical refiners crush and cut the chocolate paste until it is reduced to particles of dimensions not exceeding 18 microns.

Conching

Conching is an operation that can last for several hours and has diverse objectives: to create a perfect mix between the various components; reducing the acidic and astringent aromas; removing the residual humidity that at the end of the process will not be higher than 0.5-0.8%.

In this step a small part of soy lecithin 0.3% is added as a fluidifying agent and emulsifier, and natural extract of vanilla is added as flavouring.

Chocolate

Tempering

During tempering the chocolate is first cooled to 26°/28° and subsequently heated to 29°/32°. This is necessary so that the cocoa butter solidifies in the stable crystalline form, giving it a bright appearance, a correct break and excellent shelf life.

Modelling

The tempered chocolate is poured in drops and buttons of different shapes and sizes, then solidified in a long cooling tunnel.

Packaging

The solid chocolate and cooled is packaged in line and labelled with on-line information about the production specifications, in multiple languages for foreign markets.